You want your streetwear brand to stand out. Avoiding t-shirt customization mistakes matters more than you think. Common issues like ignoring your audience, design slip-ups, poor fabric choices, production errors, and messy order processes can hurt your brand. Customers notice these problems fast—their trust drops. Your reputation takes a hit. Take a close look at your process as you read. You might spot easy ways to improve and keep your fans happy.

Know who your buyers are. Find out what they like so you can make designs they want.

Pick good fabrics. Use soft and strong materials to make customers happy.

Make designs easy to understand. Use big pictures and clear words so shirts do not look messy.

Check designs for mistakes. Look for errors before printing to look professional.

Plan custom orders well. Make sure sizes are right and shirts are made on time to keep customers pleased.

Ask customers what they think. Use surveys and reviews to make products better and help people trust your brand.

Watch for new trends. Keep up with changes so your brand stays cool and interesting.

Do quality checks often. Check shirts regularly to find problems early and keep products good.

You want your streetwear brand to reach real people. Selling shirts is not enough. If you ignore your audience, your designs may not work. Your message can get lost. When you know your fans, they get excited and stay loyal. Let’s see how you can fix this mistake.

You should learn what your audience likes. If you do not research, you miss trends. You also miss what your customers want to wear.

Streetwear changes quickly. If you do not keep up, your brand looks old.

Do market research to find new styles and colors.

Watch influencers and top brands for ideas.

Use social media to see what people talk about.

Your brand story is important. If your message does not match your audience, they will not connect.

Make sure your designs and typography fit your fans’ style.

Build a brand identity that feels real.

Keep your message clear and the same everywhere.

Tip: A true story and bold typography help your brand stand out.

You cannot guess what your customers want. You need to ask them. Feedback helps you make better products and keep your audience happy.

If you ignore reviews and comments, you lose good ideas.

Use polls and surveys to learn what fans think.

Reply to comments and messages to show you care.

Change your designs based on what people say.

Reviews show what works and what does not. They help you fix problems before they get worse.

Aspect | Importance |

|---|---|

Aesthetics | Matching customer style makes them happy and engaged. |

Material Quality | Good fabrics show you care and make customers satisfied. |

Fit | Good fit and many sizes help customers feel included. |

Overall Satisfaction | Knowing what customers think helps you stay ahead. |

If you keep ignoring your audience, you may lose their trust. Here is what successful brands do:

Keep up with market trends.

Give custom options and new typography.

Work with influencers and make fun content.

Try limited edition drops to create excitement.

Streetwear fans want real stories and good quality. If you focus on these, your brand will shine.

You want your streetwear tees to feel great and last long. If you use poor fabric quality, your brand can lose fans fast. People notice when shirts feel rough, shrink, or fade after a few washes. Let’s break down the biggest fabric mistakes and how you can avoid them.

You might think saving money on materials helps your bottom line. It doesn’t. Cheap fabrics often cause problems like shading, pilling, and color bleeding. These issues make your shirts look old and worn out after just a few wears.

Fabric Quality Issue | Description | Common Causes |

|---|---|---|

Shading | Fabric tone changes between rolls or pieces | Dyeing inconsistencies |

Pilling | Tiny balls form on the surface | Weak fibers or poor finishing |

Color bleeding | Colors run during washing | Low-quality dyes |

Shrinkage | Shirts get smaller after washing | No pre-treatment |

Holes, snags, and runs | Fabric tears easily | Poor yarn quality |

Tip: Always check fabric samples before you order. Rub the fabric, stretch it, and see how it reacts to water.

You want your shirts to survive daily wear. If you skip quality checks, you risk selling shirts with crease marks, fabric stains, or yarn defects. These problems hurt your brand’s reputation. Customers expect streetwear to last through skate sessions, parties, and washes.

People buy streetwear for comfort and style. If your shirts feel itchy or shrink, buyers won’t come back. Many hoodie buyers say fit and fabric quality matter most. When you use quality materials, you get better reviews and more repeat customers.

Soft, breathable cotton keeps fans happy.

Strong stitching and pre-treated fabric prevent shrinkage.

Smooth finishes stop pilling and make shirts look fresh.

Note: Improvements in fabric quality lead to higher Net Promoter Scores and more repeat purchases.

Your brand’s reputation depends on every shirt you sell. If you keep choosing the wrong fabric, you risk public backlash. Big brands like H&M and Zara faced criticism for using hazardous chemicals and selling low-quality shirts. Fans called them out, and their reputations took a hit.

Good fabric choices show you care about your customers.

High-quality shirts help you stand out in a crowded market.

Bad reviews spread fast on social media.

If you want your streetwear brand to grow, focus on quality materials. Your fans will notice the difference, and your brand will earn their trust.

You want your streetwear t-shirts to get noticed for good reasons. Many brands make common mistakes when designing t-shirts. Let’s look at the biggest design mistakes and how you can avoid them when making custom shirts.

Some people think more graphics make a shirt better. But too many graphics can make the shirt look messy. Customers do not like shirts that are hard to understand. If you put lots of things on one shirt, the message is lost. Fans want bold and clear designs, not something confusing.

Keep your idea simple.

Use one main graphic or message.

Leave empty space so the design is easy to see.

If you use too many styles or random graphics, people may not know your brand. You want every shirt to show your brand’s story. Experts say you should use graphics that match your brand and use the same typography as your logo.

Tip: A simple and clear design helps people remember your brand.

Picking the wrong colors can make shirts hard to read. Bad color contrast is a big mistake. If your text is hard to see, people will not buy your shirt. High contrast makes it easier for everyone to read, even people with vision problems.

Choose colors that stand out.

Try your design on different shirt colors.

Make sure your message is easy to see from far away.

Colors that do not match can make your shirt look boring or too busy. People want shirts that look cool but not too wild. Too many colors can ruin the look. Use a few strong colors that fit your brand.

Mistake Type | Description |

|---|---|

Color Contrast | Bad color contrast makes designs less powerful. |

Design Placement | Bad placement makes shirts look strange or unbalanced. |

Typography | Hard-to-read fonts hurt your brand’s message. |

You need to keep your style the same on every shirt. If you change styles or where you put things, your shirts lose their special look. Visual hierarchy helps people know what to look at first. Put the most important parts where people will see them right away.

"Visual hierarchy helps people know where to look first. If it is hard to know what to look at, the layout is missing clear order." – The Nielsen Norman Group

Simple designs work best in streetwear. Use empty space to make your graphics stand out. Make sure your design fits the shirt size. Use mockups to see how your design looks on different sizes. This helps you avoid weird gaps or bad placement.

Use mockups before you finish your design.

Change the size for each shirt size.

Put graphics where they look best, not always in the middle.

If you skip these design mistakes, your shirts will look great. Your brand will look professional and more people will want to buy your shirts.

Printing can make or break your streetwear t-shirts. If you get it wrong, your shirts might look cheap or fall apart after a few washes. Many brands run into trouble because they skip important steps or pick the wrong printing method. Let’s look at the most common mistakes and how you can avoid them.

Choosing the right printing method matters a lot. If you pick the wrong one, your shirts may not last or look as good as you hoped.

You want your designs to pop. If you use the wrong technique, your prints might look blurry or faded. Some brands skip test prints or quality checks. This leads to shirts that disappoint your customers. Here are some common mistakes you should watch out for:

Picking the wrong printing technique for your fabric.

Skipping test prints and not checking quality.

Not preparing your design files the right way.

Overlooking printing methods that work best for your shirt material.

Ignoring safety and environmental standards.

Tip: Always test your print on the actual fabric before you start a big order. This helps you catch problems early.

No one wants a shirt that fades after two washes. If you don’t use durable printing methods, your graphics will not last. Some inks work better on certain fabrics. If you ignore this, your shirts might stretch, crack, or fade fast. Customers notice when product quality drops, and they may not buy from you again.

Your design might look great on a screen, but printing brings new challenges. If you don’t match your design to the print method, you could end up with shirts that look nothing like your mockups.

Some printing methods can’t handle every color. If you use too many shades or the wrong type of color, your print might look dull or off. Customers expect the colors they see online to match what they get. When colors don’t match, people feel let down.

Share mockups with your customers before printing.

Include exact color codes and placement details in your proofs.

Bad placement can ruin a great design. If your graphic sits too low, too high, or off-center, the shirt looks awkward. Many brands forget to check how the design fits on different sizes. This leads to shirts that feel unbalanced or just wrong.

Always check your design on real shirt templates.

Get feedback from others before you print.

Make sure your design fits every size you offer.

Note: Inaccurate proofs or mockups can lead to unhappy customers if the final shirt doesn’t match what they expected. Pay close attention to placement and sizing to avoid these custom apparel printing mistakes.

Overlooking printing methods and not matching your design to the right print process are common mistakes. If you fix these, you’ll boost your product quality and keep your fans coming back for more.

You want every t-shirt to look great before customers get them. If you skip checking the final design, you might send out shirts with mistakes. These mistakes can hurt your brand. Let’s talk about why this step is important and how to avoid design problems.

Sometimes, you might want to hurry and skip proofing. That is not a good idea. Proofs help you find mistakes before making the shirts.

If you do not check proofs, you can miss spelling errors, blurry pictures, or wrong colors. These mistakes make your shirts look bad. You want your design tips to help you, not cause problems.

Check spelling and grammar carefully.

Make sure images are clear and colors look right.

Look at placement and size on mockups.

Tip: Always look at your design on a real shirt template. This helps you see mistakes you might miss on a computer.

Mistakes cost money to fix. If you find problems after making the shirts, you may need to redo them. That wastes time and money. Most producers try to keep mistakes low, around 5-10%. If you skip proofing, mistakes can be much higher.

Source | Acceptable Error Rate |

|---|---|

T-Shirt Forums | 5-10% |

Signs101 | 5-10% (multi-color) |

You want to keep mistakes low. Proofing helps you do that.

Quality checks make sure every shirt is good. You want customers to get shirts that fit well and look nice.

During final checks, you look for problems like seams that do not line up, dye stains, or bad stitching. You also check size and fit. If you rush, you might miss these problems. Always check every batch before you ship.

Common problems you might find:

Not checking size and fit

Not testing for shrinkage or stretch

Bad stitching or seams

Note: If you find these problems early, you save money and keep your brand safe.

Before you say yes to production, use a checklist. Experts say you should include these things:

Date and place of inspection

Inspector’s name

Product and order number

Check quantity and size

Make sure style and color are right

Check labels and packaging

Test for pulling, stretching, and strength

Test buttonholes

Manufacturers check every detail, from the first proof to the last shirt. This makes sure all products look the same. If you follow these steps, you avoid design mistakes and keep customers happy.

Remember: Always proofread and check your final design before making shirts. Your brand will be glad you did.

Ordering custom shirts for your streetwear brand sounds easy, but small mistakes can cause big problems. You want every shirt to fit right, arrive on time, and look just like your design. Let’s look at the most common custom t-shirt ordering mistakes and how you can avoid them.

Getting the right size matters more than you think. If your size charts are wrong, customers will send shirts back. You lose money and trust.

Many brands use size charts that do not match their actual shirts. This confuses buyers and leads to returns. Check out these numbers:

Category | Cause of Returns | Percentage |

|---|---|---|

Men's Apparel | Fits too small | 23% |

Women's Apparel | Fits too big | 22% |

Children's Apparel | Fits too small | 31% |

Children's Apparel | Fits too big | 16% |

Sizing inconsistencies cause 53% of returns. If customers get the wrong fit, 32% stop shopping with you. That’s a huge loss for your brand.

Design placement fail is another issue. If your graphic sits too high or too low, the shirt looks awkward. You want your design to sit just right on every size. Always use real shirt templates and test your design on different sizes before you order.

Tip: Ask your manufacturer for physical samples. Try them on and check the fit and design placement before you launch.

You want your shirts to arrive on time. If you miss deadlines, customers get frustrated and may not buy again.

Missed Deadlines

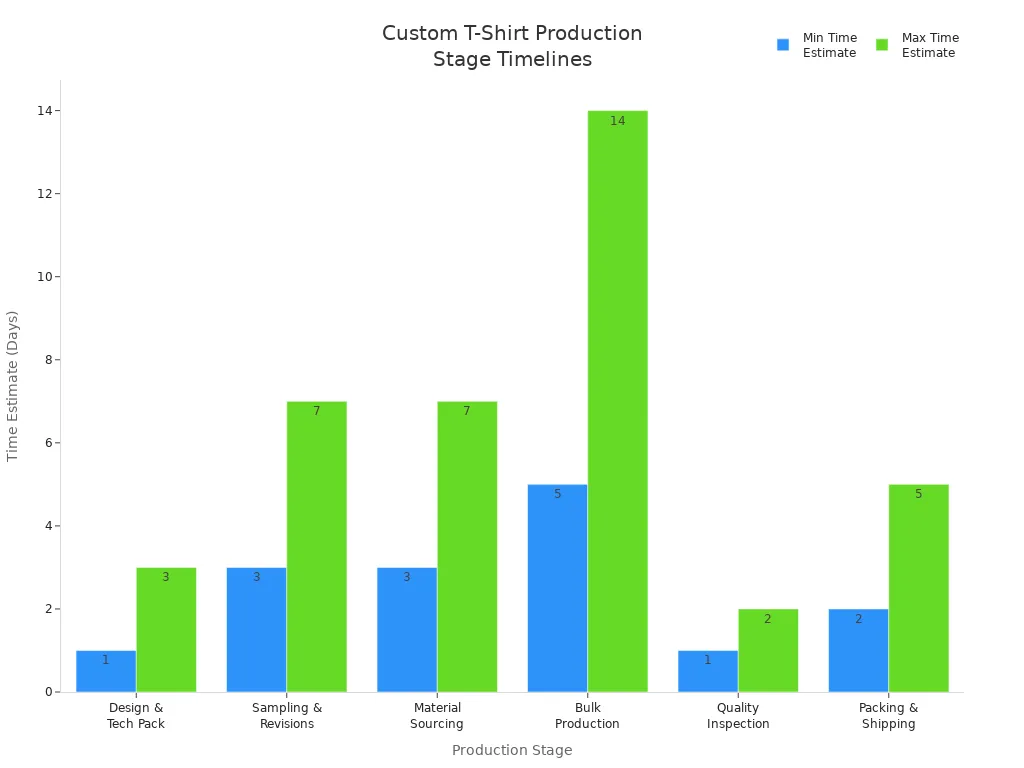

Many brands underestimate how long production takes. You might think you can get shirts in a week, but the process takes longer. Here’s a quick look at the timeline:

Production Stage | Time Estimate |

|---|---|

Design & Tech Pack | 1–3 Days |

Sampling & Revisions | 3–7 Days |

Material Sourcing | 3–7 Days |

Bulk Production | 5–14 Days |

Quality Inspection | 1–2 Days |

Packing & Shipping | 2–5 Days (air) |

15–38 Days |

If you ignore lead times or skip regular check-ins with your manufacturer, you risk production delays. Always plan for setbacks, especially with complex designs.

Running out of stock or having too many shirts can hurt your business. You need a plan to keep inventory balanced.

Proactive planning helps you avoid delays. Set a timeline with your printing company early.

Establish milestones for each stage. Stick to your schedule.

Partner with companies that use strict quality control. This keeps every shirt looking great.

Note: Negotiate prices and order in bulk when possible. You save money and reduce the risk of running out of popular sizes.

Start with clear designs and tech packs. Choose in-stock fabrics to speed up sourcing. Limit sampling rounds and work with experienced partners. These steps help you avoid custom t-shirt ordering mistakes and keep your streetwear brand running smoothly.

You want your streetwear brand to stay around for a long time. Many brands lose fans because they make mistakes that can be fixed. These mistakes include bad t-shirt design, using poor materials, and having messy custom apparel orders. If you do not listen to your audience or skip checking quality, your brand could fail like 53% of clothing lines do in four years. Here are the most important things to remember:

Learn about your audience and follow new trends.

Pick strong and comfy fabrics for every t-shirt.

Keep your design simple and bold.

Always check your final custom t-shirts before making them.

Plan your custom apparel orders and double-check sizing.

Strategy | Description |

|---|---|

Speeds up the time from design to delivery, making custom apparel more profitable. |

Try Kaizen to make small changes, use just-in-time production, and keep your workspace neat. These steps help you stop mistakes and keep your custom t-shirts looking new. Check your process today. Keep making things better and watch your brand get bigger! 🚀

You want soft, durable cotton. Many brands use 100% combed cotton or cotton blends. These fabrics feel good and last longer. Try samples before you choose.

Ask your supplier for actual shirt measurements. Test samples with friends or team members. Update your chart if you get feedback about fit problems.

You might use the wrong ink or printing method. Always match your design to the fabric and test prints before you order. Wash samples to check durability.

Use real shirt templates for every size. Print a few samples and check how the design looks on people. Ask for feedback before you launch.

Run polls on social media. Ask for reviews after each sale. Reply to comments and messages. Customers like when you listen and make changes.

Set clear deadlines with your supplier. Track each stage of production. Use a checklist for design, printing, and shipping. Plan for delays, especially during busy seasons.

Yes! You can choose organic cotton, recycled polyester, or bamboo blends. These options help your brand stand out and attract eco-conscious customers.

Tip: Always test new materials before you launch a full collection.