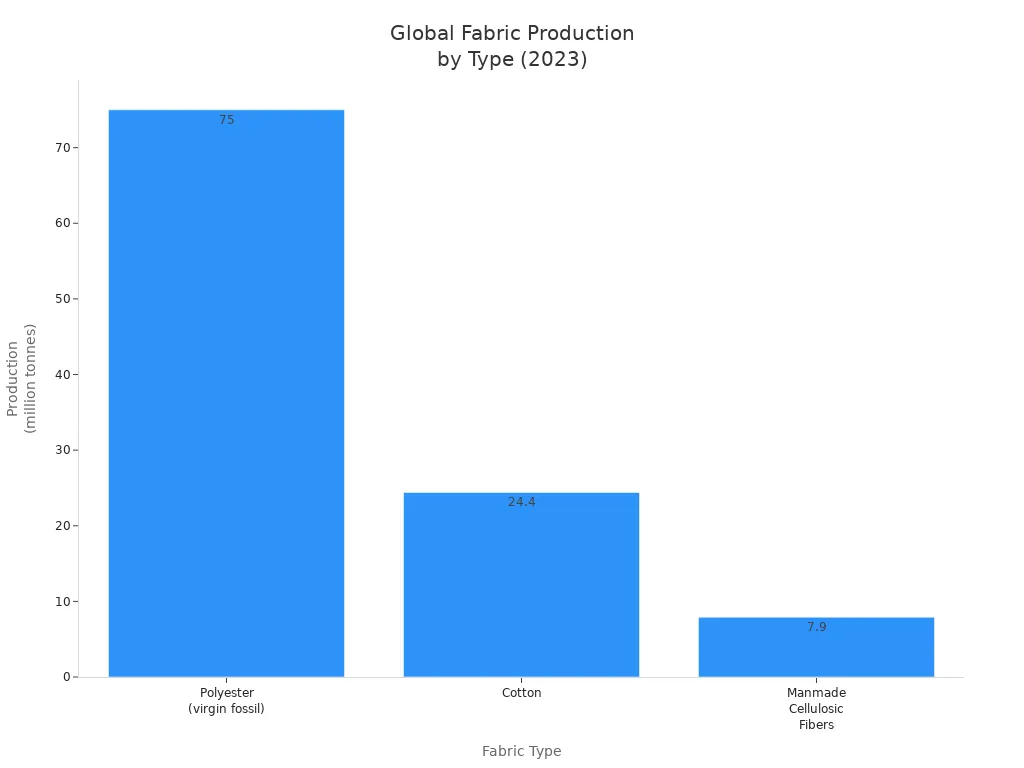

Fabric starts with picking the right fiber and follows a detailed fabric manufacturing process to become textiles. This process includes obtaining fibers, cleaning them, spinning, weaving or knitting, and finishing. Each step in the fabric manufacturing process determines how strong and comfortable the fabric will be, which in turn affects how clothes are made worldwide. Fabric plays a crucial role in clothing production and helps meet fashion and industry demands globally. The type of fiber chosen and the fabric manufacturing process used influence the price, quality, and availability of the fabric. The chart below shows that polyester, cotton, and manmade cellulosic fibers are the most widely used fibers around the world.

Fabric Type | Global Production (2023) | Market Share / Notes |

|---|---|---|

Polyester | 75 million tonnes | 57% of total fiber production |

Cotton | 24.4 million tonnes | 29% produced under sustainability programs |

Manmade Cellulosic | 7.9 million tonnes | 6% of global fiber market |

People who work in or study clothing production gain valuable insights from understanding the fabric manufacturing process. Knowing how fabric is made helps them select better materials and consider environmental impacts.

Fabric begins with fibers from plants, animals, or is made by people with chemicals. Natural fibers like cotton, wool, and silk are soft and let air pass through. Synthetic fibers like polyester and nylon are strong and simple to take care of. Mixing natural and synthetic fibers makes fabric comfy and long-lasting. Making fabric includes getting fibers, cleaning them, spinning yarn, weaving or knitting, and finishing with dye or other treatments. Weaving makes fabric that is firm and steady. Knitting makes fabric that is soft and stretchy for many uses. Picking fibers can affect the environment. Some fibers need a lot of water or energy. Others, like hemp and linen, are better for nature. New technology like digital printing and 3D printing helps make fabric faster and cuts down on waste. Wholesale fabric suppliers are important because they provide good materials and help fashion brands follow trends.

Fabric and textiles are not the same thing. Fabric is a finished material made by weaving, knitting, braiding, crocheting, or bonding fibers and yarns. People use fabric mostly for clothes and other products. Textiles is a bigger word. It means all fiber-based materials, from raw fibers to finished and unfinished things. Every fabric is a textile, but not every textile is a fabric. The table below shows how they are different:

Aspect | Fabric | Textile |

|---|---|---|

Definition | Finished material made by weaving, knitting, braiding, crocheting, or bonding fibers/yarns. | All fiber-based materials: raw fibers, yarns, unfinished and finished products. |

Production Methods | Weaving, knitting, braiding, crocheting, bonding (non-wovens). | Includes all stages: fibers, yarns, fabrics; made by weaving, knitting, bonding, etc. |

Usage | Mainly for clothing and specific finished products. | Used in clothing, industrial, medical, agricultural, and other sectors. |

Finished vs Unfinished | Always finished products. | Can be finished or unfinished. |

Relationship | All fabrics are textiles. | Not all textiles are fabrics. |

Fabric comes from two main sources. These are natural and synthetic.

Natural fibers come from plants or animals. Cotton, hemp, flax, jute, sisal, and bamboo are plant fibers. Cotton is soft and lets air through. Hemp and flax are strong and last long. Wool and silk are animal fibers. Wool is warm and soft. Silk feels smooth. People get plant fibers by retting or using machines. Animal fibers are taken by shearing or collecting.

Synthetic fibers are made by people using chemicals. Most synthetic fibers, like polyester and nylon, come from oil-based chemicals. Biosynthetics use things that grow again and are better for the climate. Manmade cellulosic fibers, like rayon, are made from wood pulp with chemicals. Other synthetic fibers are elastane, polypropylene, polyurethane, and acrylic.

Fabric is used in many ways at home and in jobs. The fiber type and how fabric is made change what it is used for. The table below lists common uses:

Category | Applications / Uses | Key Features / Notes |

|---|---|---|

Industrial Fabrics | Aerospace, apparel/clothing, architecture, automotive, chemical processing, electrical, filtration, marine, medical | Special jobs like chemical resistance, electrical conductivity, flame protection, heat insulation, weather resistance, sound proofing |

Consumer Fabrics | Clothing, bedding, rugs, curtains, furnishings | Made for comfort and looks |

Technical Textiles | Industrial, medical, and geotextiles | Made for special jobs, not looks |

Fabric Types | Woven, non-woven, knitted, tufted | How it is made changes its use; woven fabrics have direction, non-wovens are webs without yarn direction |

Fiber Types | Natural (cotton, wool, silk), Synthetic (nylon, polyester, acrylic), Inorganic (ceramic, glass fibers) | Natural fibers are used in home textiles; synthetics are used in jobs; blends mix good things from each |

Specialized Forms | Webbing (straps, belts), Batting (thermal liners), Sleeving (insulation wraps), Thread (sewing) | Used for special jobs in factories |

Note: Textiles include things for homes and for work. Home textiles are made for comfort and looks, like clothes and bedding. Technical textiles are made for special needs in jobs like medicine and building.

Natural fibers come from plants and animals. These fibers are used to make many fabrics. People like natural fibers because they are comfy and let air through. They also have special textures.

Cotton is a fiber from a plant. Workers pick cotton from the plant’s seed pods. Cotton fabric feels soft and soaks up sweat. People wear cotton in hot weather because it lets air move. Cotton is not very strong and does not stretch much. It wrinkles easily but feels nice on skin.

Wool comes from sheep’s fleece. Wool fabric keeps you warm by trapping air. Wool can stretch and go back to its shape. It soaks up water and does not smell bad. People use wool for sweaters, coats, and blankets.

Silk is made by silkworms. Silk fabric shines and feels smooth. Silk is strong and can stretch, so it hangs nicely. People like silk because it feels fancy. They use it for dresses, scarves, and ties.

Linen comes from the flax plant. Linen fabric feels cool and dries fast. Linen is strong but does not stretch much. It wrinkles a lot. People use linen for summer clothes and home items because it stays cool.

Other natural fibers are hemp, abaca, coir, mohair, cashmere, and camel hair. Each one is special. Hemp is very strong and lasts long. Cashmere is soft and rare.

Fiber | Origin | Key Characteristics |

|---|---|---|

Cotton | Plant-based | Soft, lets air through, soaks up water, medium strength, does not stretch much |

Linen | Plant-based | Strong, lets air through, soaks up water, does not stretch much, has a natural feel |

Hemp | Plant-based | Very strong, lasts long, soaks up some water, does not stretch much, good for the planet |

Wool | Animal-based | Warm, keeps heat in, stretches, soaks up water, medium strength |

Silk | Animal-based | Feels fancy, shiny, strong, stretches, soaks up some water |

Synthetic fibers are made by people. They use chemicals, often from oil, to make them. These fibers help make fabric that lasts and does not stain easily.

Polyester is the most used synthetic fiber. Factories melt chemicals and spin them into threads. Polyester fabric does not wrinkle or stain much. It dries fast and keeps its shape. People use polyester for sports clothes, uniforms, and home items.

Nylon is another well-known synthetic fiber. Factories make nylon by joining chemicals and spinning them. Nylon fabric feels smooth and is strong. It can stretch and does not wear out fast. People use nylon for sportswear, tights, and outdoor gear.

Acrylic fibers are light and soft. Factories spin chemicals to make acrylic threads. Acrylic fabric looks and feels like wool but costs less. People use acrylic for sweaters, blankets, and hats.

Synthetic fibers are liked because they last long and are easy to wash. Melt-spinning and other ways make strong, long threads. These fibers do not wrinkle or stain, so they are used in many fabrics.

Blended fibers mix natural and synthetic fibers. This makes fabric with the best parts of both.

Cotton-polyester blends are used a lot in clothes. Cotton makes the fabric comfy and lets air through. Polyester makes it strong and helps it keep its shape. Blended fabric does not shrink or wrinkle much. People pick cotton-polyester blends for sports and daily clothes.

Synthetic fibers make fabric strong, stop wrinkles, and last longer.

Blended fabrics are comfy, strong, and look good. Factories mix fibers to make fabric for different uses.

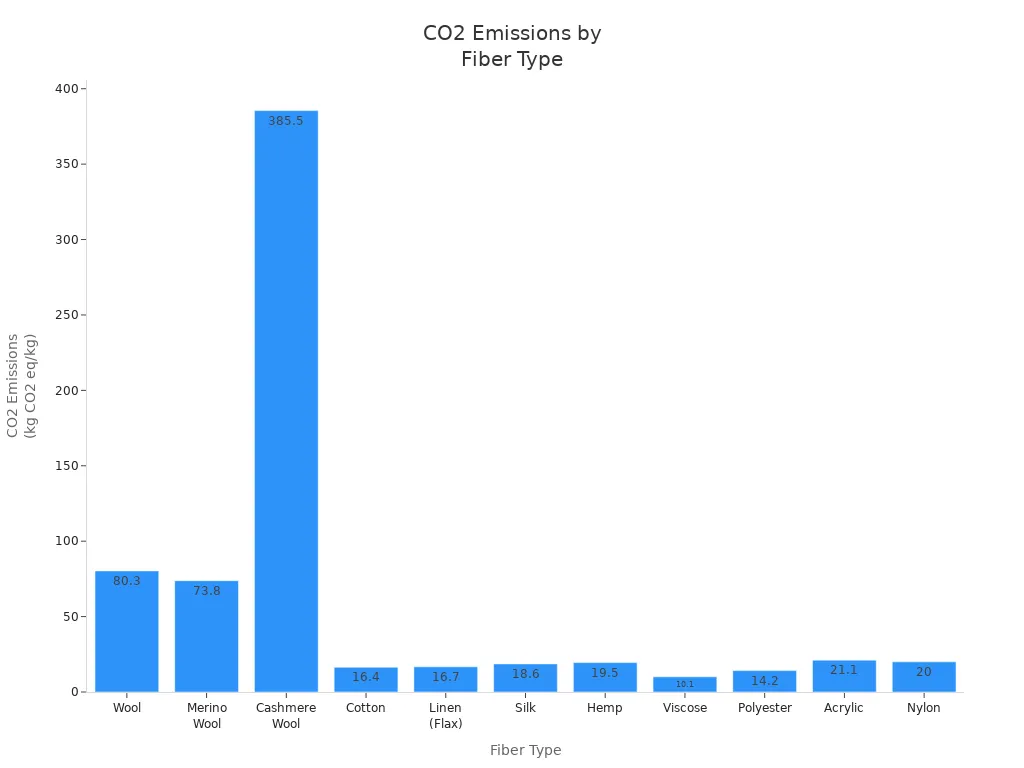

The fiber you pick can change the world in many ways. Each fiber type needs different water and energy. Some fibers make more pollution than others. Many people now care about how clothes affect the Earth.

The table below shows how common fibers hurt or help the planet:

Fiber Type | CO2 Emissions (kg CO2 eq/kg) | Water Usage (liters/kg) | Pollution Concerns | Biodegradability | Additional Notes |

|---|---|---|---|---|---|

Wool | 80.3 | 800 | Soil and water pollution from sheep farms | Yes | Methane emissions from sheep; animal welfare issues (e.g., mulesing in Merino wool) |

Merino Wool | 73.8 | 800 | Soil and water pollution from sheep farms | Yes | Animal welfare concerns; mulesing still practiced in some regions |

Cashmere Wool | 385.5 | 800 | Soil and water pollution from goat farming | Yes | Highest greenhouse gas emissions among wools |

Cotton | 16.4 | 10,000 | Fertilizer and pesticide pollution | Yes | Major water consumption; pollution from cultivation and processing |

Linen (Flax) | 16.7 | Minimal (rainwater) | Possible pesticide use; dyeing pollution | Yes | Low water use; durable; often locally produced |

Silk | 18.6 | Rainwater | Fertilizers, pesticides, and chemical use | Yes | Animal welfare concerns; killing silkworms; mostly produced in Asia |

Hemp | 19.5 | Rainwater | Possible pesticide use; dyeing pollution | Yes | Low water and pesticide needs; durable |

Viscose | 10.1 | 10,000 | Chemical pollution (solvents); deforestation | Yes | High water use; chemical solvents pollute air, water, soil; 70 million trees cut annually |

New Viscose (Tencel, Lyocell, Modal) | Not specified | Closed-loop water recycling | Sustainable forestry (FSC certified) | Yes | Eco-friendlier viscose alternatives with closed manufacturing circuits |

Polyester | 14.2 | N/A | Microplastic pollution; chemical use | No | Derived from petroleum; energy-intensive; releases microfibers during washing |

Acrylic | 21.1 | N/A | Microplastic pollution; chemical use | No | Derived from petrochemicals; energy-consuming; pills easily |

Nylon | 20 | N/A | Microplastic pollution; chemical use | No | Energy-intensive; releases potent greenhouse gases; short lifespan; long degradation time |

Some fibers, like cotton and wool, come from plants or animals. These fibers break down in nature. But they can use a lot of water or land. Cotton needs about 10,000 liters of water for one kilogram. Wool makes a lot of greenhouse gases because sheep give off methane. Cashmere makes even more greenhouse gases than other wools.

Synthetic fibers, like polyester, nylon, and acrylic, are made from oil. Factories need lots of energy to make them. These fibers do not break down fast. When people wash polyester or nylon, tiny plastic bits called microplastics go into rivers and oceans.

Linen and hemp use less water and fewer chemicals. Linen often grows with just rainwater. It does not need much pesticide. Hemp grows fast and does not need much water or chemicals. These fibers are strong and last a long time.

Viscose and rayon are made from wood pulp. Making them can hurt forests and pollute water if not done right. Newer types, like Tencel and Lyocell, use closed systems to recycle water and chemicals. This makes them safer for the planet.

♻️ Recycled fabrics help cut down on waste and save resources. Using recycled polyester or cotton means we need fewer new materials. The circular economy asks people to reuse, fix, and recycle fabrics to help the Earth.

Key things to know about fiber impact:

Polyester is strong and easy to wash, but it uses a lot of energy and makes microplastic pollution.

Wool is natural and breaks down in soil, but it uses land and water and makes methane.

Linen and hemp are good for the planet. They use little water and few chemicals.

Recycled fabrics and circular ideas help lower the harm of making new fabric.

Picking the right fiber can help protect nature and make a better future for all.

The fabric manufacturing process changes raw materials into fabric. This happens in a series of steps. Each step affects how the fabric will feel and work. The process starts with getting fibers. Then, workers prepare, spin, and form the fabric.

Manufacturers start by getting raw materials. They collect natural fibers from plants and animals. Cotton is picked from fields. Wool is cut from sheep. Silk is taken from silkworm cocoons. Synthetic fibers like polyester and nylon are made in factories. These factories use chemicals from oil to make them. The type of raw material changes how strong and soft the fabric is.

After collecting fibers, workers clean them. They take out dirt, seeds, and other things. Cotton goes through ginning to remove seeds. Wool is washed to get rid of grease and dirt. Synthetic fibers are cleaned during their making. Clean fibers help make better fabric. Checking quality now stops problems later.

Carding and combing get fibers ready for spinning. Carding machines untangle and line up fibers. This makes a soft sheet and removes short pieces. Combing makes fibers even straighter and cleaner. Combed fibers are smoother and stronger. This helps make better yarn and fabric. These steps are needed for good textiles.

Note: Good cleaning, carding, and combing make fabric last longer. They also make it softer and look better.

Spinning turns fibers into yarn. Machines pull and twist the fibers together. The twist changes how strong and soft the yarn is. More twist makes yarn stronger. Less twist makes it softer. There are different spinning methods. Each one makes yarn with special features.

Yarn thickness is also called yarn count. It is important in making fabric. Thick yarns make heavy, strong fabric. Thin yarns make light, soft fabric. Factories set machines to control yarn thickness. The thickness depends on what the fabric will be used for. Denim uses thick yarns. Silk scarves use thin yarns.

Tip: Yarn quality depends on fiber length, twist, and speed. Checking quality during spinning helps make good yarn for the next steps.

Weaving is a way to make fabric. It uses two sets of yarns. One goes up and down, the other goes across. Looms cross these yarns to make a strong fabric. Woven fabrics do not stretch much and keep their shape. They are used for shirts, pants, and furniture. Weaving can make different patterns like plain, twill, or satin.

Feature | Weaving |

|---|---|

Yarn Sets Used | Two (warp and weft) |

Elasticity | Low |

Stability | High |

Common Uses | Denim, canvas, dress shirts |

Knitting makes fabric by looping one yarn. Machines or needles make these loops. This makes the fabric stretchy and soft. Knitted fabrics are comfy and let air through. They are good for t-shirts, sweaters, and socks. Knitting is faster and costs less than weaving. Knitted fabric stretches more and does not wrinkle easily.

Feature | Knitting |

|---|---|

Yarn Sets Used | One (looped) |

Elasticity | High |

Stability | Lower than woven |

Common Uses | T-shirts, sweaters, socks |

Block Quote: Weaving makes firm, less stretchy fabric. Knitting makes stretchy, flexible fabric. The method depends on what the fabric will be used for.

The fabric manufacturing process has many steps. It starts with raw materials and ends with weaving or knitting. Each step changes how the fabric looks and lasts. Checking quality at every step is important. The right process makes fabric for many uses, like clothes and industry.

After making fabric, workers finish it. This step gives fabric its final look and feel. Finishing gets fabric ready for clothes, homes, or factories. There are many finishing steps. These steps help fabric look better and work well.

Dyeing puts color on fabric. Workers use dyes to change the color. They can dye fibers, yarns, or finished fabric. Each way makes colors look different. Dyeing fibers gives deep, even colors. Dyeing fabric lets styles change fast.

Dyeing changes how fabric looks and lasts. Good dyeing keeps colors bright after washing and sun. Bad dyeing can make colors fade or look uneven. Factories use special dyes for each fiber. Some dyes work best on cotton. Others are better for polyester or nylon.

Tip: Dyeing does more than add color. It can make fabric feel softer or give it a special finish.

Printing adds pictures or patterns to fabric. Factories use screen printing, digital printing, or block printing. Each way makes different designs. Screen printing is good for bold, simple shapes. Digital printing makes detailed, colorful images.

Printing changes how fabric looks. It can add flowers, stripes, or logos. Printing quality depends on ink, fabric, and method. Good printing keeps patterns clear and colors bright after washing.

Printing also changes how fast fabric is made. Digital printing is quick and flexible. It helps factories follow new styles. Screen printing takes longer but makes strong designs.

Treatments are extra steps that help fabric work better. Workers add treatments to make fabric water-repellent, flame-retardant, or wrinkle-free. Some treatments make fabric softer or shinier.

Factories use machines, chemicals, or heat for treatments. Machines like calendaring and brushing change the surface. Chemicals add stain resistance or stop germs. Heat sets the shape or cleans the fabric.

The table below lists common finishing steps and what they do:

Finishing Process Type | Examples | Effects on Performance | Effects on Appearance |

|---|---|---|---|

Mechanical Finishes | Calendaring, Brushing, Embossing | Makes fabric softer and warmer | Smooths or adds shine and texture |

Chemical Finishes | Water repellency, Flame retardancy, Stain resistance | Adds protection and makes care easy | Changes shine, feel, or color strength |

Thermal Finishes | Heat setting, Singeing, Pre-shrinking | Keeps shape and stops shrinking | Makes fabric neat and smooth |

Aesthetic Finishes | Dyeing, Printing, Embossing | Makes colors brighter and adds patterns | Improves style and looks |

Performance Finishes | Antimicrobial, UV protection, Durable press | Helps keep fabric clean and safe | Keeps fabric looking new |

Treatments help fabric last longer and work better. Water-repellent finishes keep jackets dry. Flame-retardant finishes make uniforms safer. Antimicrobial finishes stop germs on hospital sheets.

Note: The right finishing step can turn plain fabric into something special. Finishing decides how fabric looks, feels, and works every day.

Finishing is the last step in making fabric. It makes colors brighter, adds patterns, and gives special features. Careful finishing makes fabric high quality and ready for clothes, furniture, and other products.

Textile making started a long time ago. Early people used plant fibers and animal skins. This began about 12,000 years ago. In ancient times, people spun and wove with simple tools. Flax fibers from 34,000 BCE show textiles were important. Old civilizations like Egypt and Mesopotamia made weaving better. They invented the spindle and loom. These tools made fabric stronger and easier to make. The Silk Road helped spread silk and ideas. It connected Asia, the Middle East, and Europe. In the Middle Ages, wool was the main fabric in Europe. Guilds kept textile secrets safe. The Industrial Revolution changed textile making. New machines made fabric faster and cheaper. In the 1900s, nylon and polyester were invented. Today, factories use old and new ways to make textiles. Technology and culture shape what people wear.

Modern factories use new technology to make textiles. These changes help make fabric better and faster.

Factories use smart machines to make fabric quickly and waste less.

Digital printing and design software help make custom fabrics.

AI and sensors check fabric quality and find problems fast.

Recycling and upcycling turn old textiles into new things.

ERP and IoT devices track fabric from factory to store.

Nanotechnology gives fabric special features like water resistance.

New plant fibers like hemp and bamboo help the planet.

3D printing is a new way to make textiles. Special printers build fabric layer by layer. Designers can make cool shapes and patterns. 3D printing uses only the material needed. This means less waste. Companies use 3D printing for shoes and accessories. Some even make parts of clothes this way. 3D printing helps save resources and allows custom designs.

Sustainability is very important in textiles now. Companies and buyers want fabric that is good for the planet.

Eco-friendly materials do not hurt nature. Organic cotton, recycled polyester, and Tencel are popular. Some companies use fibers from algae or mushrooms. These materials break down naturally and do not pollute. Waterless dyeing and digital printing save water and chemicals. 3D knitting makes clothes without seams, so there is less waste. Many brands focus on eco-friendly products because people care about nature.

Tip: Eco-friendly textiles help protect nature and make the future cleaner.

Ethical production means treating workers and nature well. Factories use less water and energy. Workers get fair pay and good treatment. RFID and blockchain help track where fabric comes from. Enzyme finishing replaces harsh chemicals and lowers pollution. Big companies use robots and AI to cut waste and work faster. These steps make textiles better for people and the planet.

Note: Eco-friendly and ethical ways are changing textiles and fashion for the future.

The supply chain for making clothes has many steps. Each step changes how the clothes turn out. It also affects price, quality, and speed. The process starts with design and ends with people buying clothes. Here are the main steps in making clothes:

Designers think of new styles and patterns. They make samples to test their ideas.

Companies pick and buy fabric and other materials. They check if the materials are good and eco-friendly.

Factories cut, sew, and put together clothes. Workers and machines check for mistakes and follow rules.

Finished clothes travel from factories to stores or warehouses.

Companies keep clothes in warehouses and track them for fast delivery.

Stores and websites sell clothes to shoppers.

People buy and wear the clothes.

Every step needs good planning and teamwork. If one step is slow or wrong, it can mess up the whole process. Companies use computers and apps to watch products and work faster.

Tip: A strong supply chain helps brands give customers good clothes quickly and at a fair price.

Ethical practices help workers, communities, and nature. Companies must pay fair wages and keep workers safe. They should use eco-friendly materials like organic or recycled fabric. Brands need to work with suppliers who care about the same things.

Being open is important in the fabric supply chain. Companies use maps, checks, and digital tools to follow materials and make sure they are sourced right. They collect information from suppliers and look for safe and certified practices. Many brands use new tech like blockchain and Digital Product Passports to show where materials come from.

Note: Ethical clothing manufacturing helps customers trust brands and makes brands look better.

Sustainable fabric sourcing means using less packaging and picking things that break down easily. Groups like the Sustainable Apparel Coalition and Better Cotton Initiative help companies do the right thing. When brands, suppliers, and workers work together, everyone benefits.

Wholesale fabric suppliers are very important in fashion. They help brands and factories make clothes. These suppliers give fabrics, buttons, and zippers to companies. Their job is to send materials on time and check quality.

Fiber producers give natural and synthetic fibers. These fibers are needed for making fabric. They can change how much fabric costs and how easy it is to get.

Textile chemical and dye suppliers sell chemicals for finishing fabric. These chemicals change how fabric works and how green it is.

Wholesale fabric suppliers help brands make more clothes and keep quality the same. They also affect how much clothes cost and if they follow green rules.

Fashion brands need these suppliers to get materials fast. They use fabric mills, converters, jobbers, and distributors. Each one has special good points, like small orders or lower prices. Wholesale suppliers help brands keep up with new styles and what people want.

Note: Wholesale fabric suppliers help fashion companies keep good quality and change with new trends.

Picking the right wholesale fabric supplier is very important. Brands look at many things to choose the best one:

Years in business show if a supplier can be trusted.

Suppliers with new and cool products know what people want.

Good customer service means the supplier answers fast and helps.

Customer reviews tell how well the supplier does their job.

Extra things like custom printing or color choices are helpful.

Brands should ask about how long orders take, samples, and returns.

It is good to know the smallest order size and license rules.

Brands search for suppliers online, at trade shows, and in books. They ask for samples to check fabric feel, color, and look. Brands compare prices, shipping, and order sizes to save money. Talking clearly and working together can get better deals and rules.

Tip: Talking often and clearly with suppliers helps stop mistakes and makes quality better.

Wholesale fabric suppliers make sure there is good quality and lots of choices. They go to trade shows to meet brands and show new fabrics. Trade shows help suppliers learn about new styles and ideas. Brands can touch and see fabrics to check quality.

Suppliers have many fabrics, patterns, and colors for brands.

They give samples so brands can check before buying.

Many suppliers let brands pick special prints or colors for their needs.

Brands find good suppliers by talking to other stores and using sites like LinkedIn. Sharing tips with other businesses can help get better prices and service. By caring about quality and choices, wholesale fabric suppliers help brands make cool and strong products for shoppers.

The way fiber turns into fabric is important for making clothes. The fiber you pick can change the environment and cost. This makes choosing fabric a big decision. The steps are getting fibers, cleaning them, spinning, weaving or knitting, and finishing. Each step changes how the fabric feels, looks, and lasts. People who work in fashion or study it learn a lot from this process. It helps them make smart choices when making clothes. Getting fabric the right way and knowing where it comes from is fair and good for the planet. Brands should always check where their fabric is from and how suppliers affect making clothes.

Step | Description |

|---|---|

Fabric Selection & Sourcing | Choosing raw materials for good quality and the planet |

Fabric Pre-Treatment | Washing, coloring, and making fabric softer |

Pattern Making & Grading | Making and changing patterns for all sizes |

Sample Development & Testing | Making test clothes to check fit and sewing |

Fabric Cutting & Marking | Cutting fabric pieces the right way |

Sewing & Assembly | Sewing pieces together to make clothes |

Finishing & Quality Control | Checking and labeling to keep clothes nice |

Packaging & Distribution | Packing and sending clothes to stores |

Tip: Learning every step in making clothes helps brands earn trust and give people the safe, fair, and green clothes they want.

Fabric is made by weaving, knitting, or bonding fibers. Textile means all fiber-based materials, finished or unfinished. Every fabric is a textile, but not all textiles are fabric.

Natural fibers like cotton and wool feel soft and let air through. Synthetic fibers like polyester and nylon make fabric strong and easy to clean. Mixing both types can make fabric comfy, tough, and last longer.

Fabrics wrinkle because of their fiber type and how they are made. Cotton and linen wrinkle easily since they are natural fibers. Polyester and blends do not wrinkle much. Special treatments can help fabrics stay smooth.

A fabric is sustainable if it uses less water, energy, and chemicals. Sustainable fabrics often come from recycled or organic sources. Hemp, linen, and Tencel are good eco-friendly choices. Brands also want fair work and safe factories.

Dyeing puts color on fabric. The way and type of dye change how bright and long the color lasts. Some dyes work best on certain fibers. Good dyeing keeps colors bright after washing.

Yes, many fabrics can be recycled. Factories turn old cotton, polyester, and wool into new yarns and fabrics. Recycling helps cut down on waste and saves resources. Some brands use recycled materials for new clothes.

Wholesale fabric suppliers give lots of fabric to brands and factories. They help companies get the right materials fast. Suppliers offer many types, colors, and patterns for different needs.

Weaving uses two sets of yarns crossed together. This makes fabric strong and keeps its shape. Knitting uses one yarn looped together. Knitted fabric stretches more and feels softer. Each way makes different textures and uses.