In the world of customized streetwear, every detail matters — from fabric texture to stitching precision. But one element that often surprises new buyers is how different logo processes can dramatically affect the final price.

At Hangzhou Aiqi Clothing Technology Co., Ltd., a professional streetwear manufacturer specializing in custom design, we often receive questions like:

“Why does embroidery cost more than screen printing?”

“What’s the difference between puff print and heat transfer?”

This article breaks down the major logo-making processes used in streetwear production, why they result in different pricing, and how to choose the right one for your brand.

A logo process refers to the method used to apply your brand’s design, symbol, or artwork onto a garment. Each method uses different materials, techniques, and equipment — which directly influence cost, durability, and visual effect.

Common logo processes include:

Screen printing

Embroidery

Heat transfer printing

DTF (Direct to Film) printing

Puff or 3D printing

Silicone or rubber patches

Each of these methods adds a unique character to your streetwear line — but they also come with different production costs.

Screen printing remains one of the most popular and affordable methods for streetwear logos. It involves pressing ink through a mesh stencil onto the garment surface.

Pros:

Vibrant, durable colors

Excellent for bulk production

Works well on cotton fabrics

Cons:

Setup cost for each color

Not ideal for complex or multi-color designs

Why the Price Differs:

Screen printing is cost-effective for large orders because the setup cost spreads over many pieces. However, for small batches or multi-color designs, costs rise sharply due to additional screens and inks.

Embroidery involves stitching your logo with colored threads, giving it a rich, textured look.

Pros:

Premium, long-lasting finish

Suitable for caps, hoodies, and heavy fabrics

Adds texture and dimension

Cons:

Higher cost due to manual setup and machine time

Limited for small or highly detailed designs

Why the Price Differs:

Embroidery costs depend on stitch count — more intricate designs require more time and thread. This makes embroidery ideal for high-end streetwear or limited editions where brand perception matters more than cost savings.

Heat transfer applies a printed design to the garment using heat and pressure. It’s often used for detailed, colorful images.

Pros:

Works on various materials

Great for small quantities

Sharp, high-resolution results

Cons:

May peel over time

Less breathable than direct print

Why the Price Differs:

Though setup costs are low, heat transfer materials can be pricey, especially for specialty finishes like metallic or reflective films. This method balances speed and quality, perfect for smaller brands testing new designs.

DTF printing uses a digital printer to create designs on film, which are then transferred onto the garment.

Pros:

High detail and color accuracy

Works on multiple fabric types

No screen setup needed

Cons:

Slightly higher cost for inks and films

Requires precise temperature control

Why the Price Differs:

DTF printing’s technology allows for low-volume customization without expensive setup. However, ink and film costs increase the per-piece price compared to screen printing in bulk.

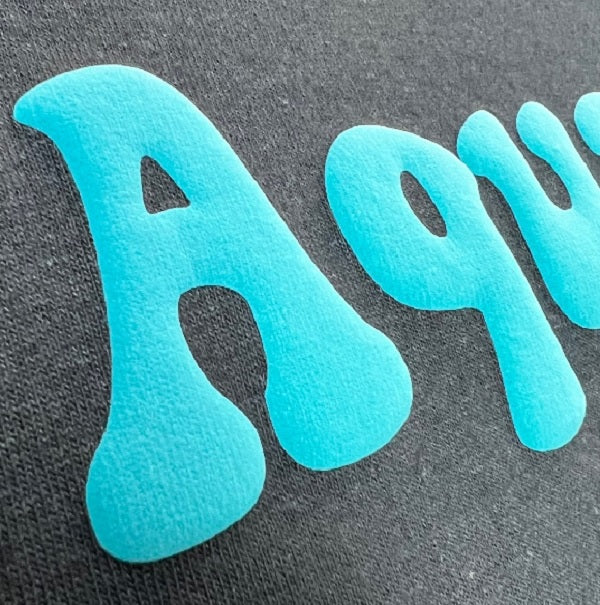

The puff printing technique uses heat-reactive ink that expands when cured, creating a 3D effect.

Pros:

Unique tactile design

Perfect for streetwear aesthetics

Highly customizable look

Cons:

Limited color options

More expensive materials

Why the Price Differs:

Because puff inks are specialized and require careful temperature control, production costs rise. However, the result is an eye-catching 3D logo that elevates your brand image — making it a top choice for fashion-forward streetwear.

Silicone patches are molded from soft rubber material and then heat-sealed or stitched onto the fabric.

Pros:

Extremely durable

3D look and waterproof

Enhances perceived value

Cons:

Higher material and tooling costs

Longer production time

Why the Price Differs:

The molding process requires custom tools and manual labor, so initial costs are higher. However, for brands focused on luxury streetwear, silicone patches deliver a bold, premium identity.

![]()

| Logo Process | Ideal For | Price Level | Durability | Key Feature |

|---|---|---|---|---|

| Screen Printing | T-shirts, hoodies | ★★☆☆☆ | High | Best for bulk |

| Embroidery | Hoodies, caps | ★★★★☆ | Very High | Luxury feel |

| Heat Transfer | Mixed fabrics | ★★★☆☆ | Medium | Fast & flexible |

| DTF Printing | All fabrics | ★★★☆☆ | High | Detailed images |

| Puff Printing | Hoodies, sweatshirts | ★★★★☆ | Medium | 3D effect |

| Silicone Patch | Jackets, caps | ★★★★★ | Very High | Premium look |

At Hangzhou Aiqi Clothing Technology Co., Ltd., we don’t just manufacture — we consult and guide our clients on selecting the best logo process for their target audience and budget.

Our in-house design and production teams ensure:

Cost-efficient material sourcing

Strict quality control at every stage

Seamless customization for bulk or small orders

Expert guidance on print methods for your fabric type

Whether you want affordable streetwear for brand launches or luxury limited-edition drops, our expertise ensures consistent quality and fair pricing.

Choosing between different logo processes isn’t just a technical decision — it’s a branding choice.

Each process reflects a distinct style, cost structure, and customer perception. Screen printing works best for affordability, embroidery for prestige, and puff or silicone for trend-setting designs.

At Aiqi Clothing, we combine manufacturing precision with creative design consulting, helping streetwear brands build strong visual identities without overspending.

If you’re planning your next custom collection, reach out to our experts — we’ll help you find the perfect logo process to match your vision and budget.