Apparel brands face a crucial decision. From nimble streetwear startups to massive global companies, they must choose where to manufacture their products. China has become the go-to choice for most. Why? The answer lies in four key advantages: a complete supply chain, unbeatable cost savings, massive production capacity, and top-notch craftsmanship.

This guide explains why brands source T-shirts and hoodies from China. You'll learn if it's right for your brand. We'll also show you exactly how to work with Chinese manufacturers.

We wrote this for startup founders, brand managers, and online sellers. If you want to build a strong, profitable clothing business, this guide is for you. We skip the surface-level advice and give you real insights from years in the industry.

Here's what you'll discover:

The four main reasons China dominates clothing manufacturing.

How to decide if Chinese production fits your brand's needs.

A clear, step-by-step production process.

How to find and work with the right factory.

China's manufacturing success isn't just about cheap labor anymore. That's an outdated view. Today, it's a sophisticated system built on four strong foundations. Together, they create advantages no other country can match.

The biggest advantage is having everything in one place. Often, you'll find fabric mills, dye houses, zipper suppliers, and printing shops all within the same area.

This close proximity changes everything.

It cuts down lead times dramatically. It also reduces the cost of moving materials around.

Compare this to manufacturing elsewhere. You'd often need to import fabric or accessories from China anyway. This adds weeks or months to your timeline. It also increases shipping costs.

China's vertical integration means faster product development. You can go from idea to finished product much quicker.

China produces more textiles than any other country. According to Statista, China's textile exports hit about 147.6 billion U.S. dollars in 2022. This massive scale means almost any material you need is available locally.

Basic cotton jersey for T-shirts? Available. Specialized technical fabrics for sportswear? Also available. You won't wait for international shipments. This speeds up your product development and gives you more creative options.

For detailed trade data, check the World Trade Organization's statistics portal.

Cost isn't just about "cheap labor" anymore. It's about total value and efficiency. Chinese workers are skilled and experienced. They operate advanced machinery and handle complex sewing techniques with fewer mistakes.

This efficiency combines with huge production volumes. Factories spread their overhead costs across millions of units. The cost of machinery, maintenance, and management becomes much lower per garment.

Raw materials cost less too. When you source fabric directly from a local mill, you skip the markups and shipping fees that importers add.

This creates better overall value. You get a high-quality, well-made garment at a price that's hard to match in Western countries. This means better profit margins for your brand.

Cost Component | Sourcing in China | Sourcing in Western Europe/USA |

Raw Fabric Cost | Lower (Direct from mill) | Higher (Often imported) |

Skilled Labor | Moderate cost, high efficiency | High cost, variable efficiency |

Overhead/Tooling | Low (Spread across high volume) | High (Lower volume per factory) |

Logistics | Highly efficient, competitive | High domestic shipping costs |

Overall Value | Excellent | Premium |

Growing brands need flexible production. China's manufacturing setup handles this perfectly.

Factories can work with different order sizes. Many modern manufacturers offer flexible Minimum Order Quantities (MOQs). Sometimes as low as a few hundred pieces per design.

This helps new brands test designs without huge inventory risks.

As your brand grows, the same manufacturer can scale with you. Going from a 500-piece test to a 50,000-piece production run is routine.

We've seen brands start with small orders and scale to tens of thousands within a year. A good Chinese partner makes this growth smooth. You won't need to find and vet new, larger factories as you expand.

This flexibility reduces growing pains. You can focus on marketing and sales while your production keeps up with demand.

The idea that Chinese factories only make low-quality basics is decades old. Today, China leads in advanced craftsmanship and technology for clothing.

Manufacturers have invested heavily in modern equipment. Automated fabric cutters and state-of-the-art sewing machines ensure precision and consistency.

This is especially true for decorating T-shirts and hoodies. Chinese factories offer many high-quality printing and embroidery options.

You can access Direct-to-Garment (DTG) printing for complex graphics. Screen printing for durability. Textured puff prints, detailed embroidery, and custom appliqué work.

This technology means your creative vision isn't limited. Complex designs that might be too expensive or impossible elsewhere are often standard in well-equipped Chinese factories.

For more on printing techniques, check Printful's guide to printing techniques.

This focus on technology and skill ensures your final product meets the quality standards of demanding customers in Western markets.

Understanding these advantages is step one. Step two is figuring out if sourcing from China fits your specific brand goals, budget, and size. The answer varies for each type of business.

New streetwear and fashion startups face unique challenges. Limited budgets, meeting minimum orders, and creating standout products top the list.

Modern Chinese factories address these issues directly. Flexible MOQs mean you don't tie up all your money in one big order. You can produce smaller, manageable quantities to test the market.

The customization options are a startup's biggest asset. You can work with factories to find unique fabrics, develop custom colors, and create complex graphics. This is impossible with off-the-shelf blank products.

This lets new brands compete on design and quality, not just price. A reliable partner helps turn creative ideas into professional, high-quality products. This gives you a competitive edge from day one.

Established clothing companies have different priorities. Supply chain stability, consistent quality at scale, and ethical compliance matter most.

An established Chinese manufacturer becomes a reliable partner for core products like T-shirts and hoodies. They can handle high-volume, repeat orders without quality compromises.

These factories have strict quality control systems at every production stage. This ensures the 10,000th hoodie matches the first approved sample perfectly.

Top-tier factories work with global brands regularly. They follow international standards for social and environmental compliance. They provide certifications like BSCI (Business Social Compliance Initiative) or ISO 9001. This assures ethical and responsible production.

This reliability reduces supply chain risks and ensures steady flow of your best-selling products.

Sellers on Shopify, Amazon, or Etsy focus on profit margins and inventory management. Sourcing from China addresses both needs directly.

Cost-effective Chinese manufacturing allows greater markups and healthier profit margins. This gives you more room for marketing spend, customer acquisition, and competitive pricing.

Production lead times are longer than print-on-demand services. But they're fast enough to restock popular items effectively. Ordering in batches of a few hundred lets you maintain inventory of winners while avoiding high per-unit costs of on-demand services.

This model also enables product testing. You can introduce new T-shirt designs with relatively low-risk batch orders. If they sell well, you can quickly reorder larger quantities. If not, you haven't committed huge amounts of capital.

Sourcing from China gives e-commerce sellers a professional supply chain and significant competitive advantage in crowded marketplaces.

Manufacturing for the first time can seem overwhelming. But it follows a logical, step-by-step process. This playbook simplifies the process and helps you communicate effectively with factory partners.

The tech pack is the most important document in clothing manufacturing. It's your garment's blueprint.

A tech pack provides detailed technical specifications that leave no room for interpretation. Sending factories just mockups or photos is a common mistake. This leads to errors and delays.

A professional tech pack must include:

Technical Drawings: Flat sketches of the garment from front, back, and side views.

Measurements: Complete size specifications for every size you plan to produce.

Fabric Specifications: Details on fabric type (like 100% combed cotton jersey), weight (like 220 GSM), and composition.

Color Codes: Official Pantone color codes for fabrics and prints to ensure color accuracy.

Construction Details: Notes on stitching, seams, and special construction methods.

Artwork & Trim Details: Placement, size, and specifications for logos, prints, labels, zippers, and drawstrings.

Instead of saying "heavy grey fabric," specify "320 GSM, 80% Cotton 20% Polyester Fleece, Color: Pantone 17-0000 Cool Gray." This level of detail is essential for professional production.

Once the factory has your tech pack, the next step is finding materials. A good partner uses their network of mills to find the perfect fabric for your T-shirts and hoodies.

Common options include:

Combed Cotton: Softer, stronger version of regular cotton, ideal for premium T-shirts.

Fleece: Soft, warm fabric with brushed interior, perfect for classic hoodies.

French Terry: Fabric with loops inside and smooth surface outside, used for lighter sweatshirts and tracksuits.

Always specify fabric weight, measured in Grams per Square Meter (GSM). Standard T-shirts are around 180-200 GSM. Heavyweight hoodies can be 350-500 GSM.

For sustainability-focused brands, factories can source organic cotton, recycled polyester, and other eco-friendly materials. Textile Exchange provides information on sustainable textile standards.

Never go to mass production without approving a sample. The sampling process is a critical checkpoint. It ensures the factory understands your vision perfectly. It typically happens in stages.

Proto Sample: The first sample made from your tech pack. It checks pattern, fit, construction, and overall look. You provide feedback for revisions.

Salesman Sample (SMS): Once the proto is revised and closer to perfect, a salesman sample may be created. This higher-quality sample is used for marketing photoshoots or showing wholesale buyers.

Pre-Production Sample (PPS): The final, perfect sample made with correct fabrics, colors, and trims. The PPS is the gold standard. Once approved, it becomes the benchmark for every piece in mass production.

Don't approve mass production until you're 100% satisfied with the Pre-Production Sample.

With an approved PPS, the factory begins mass production. Fabric gets cut in bulk, sewing lines are set up, and garments are assembled.

Quality control (QC) isn't just a final step. It's integrated throughout the process.

Inline Inspections: QC staff check garments at various production points to catch errors early.

Final Inspection: Once production is complete, a percentage of finished garments are inspected using professional standards called AQL (Acceptable Quality Limit).

AQL defines how many defective units are acceptable in a batch. AQL 2.5 is common for consumer goods. Understanding this helps you have professional quality discussions with your factory. Learn more about AQL standards from quality control firms like QIMA.

The final step is getting products from factory to your warehouse. Two primary options are sea freight and air freight.

Sea Freight: Most cost-effective for bulk shipments. Much slower, typically taking 30-40 days to reach North America or Europe.

Air Freight: Significantly faster, often taking 5-10 days. Much more expensive and usually reserved for urgent restocks or high-value items.

You'll also need to discuss Incoterms with your factory. These standardized trade terms define seller and buyer responsibilities. Common terms include FOB (Free On Board), where the factory handles getting goods to port, and EXW (Ex Works), where you handle pickup from the factory.

Major carriers like DHL provide excellent resources explaining international shipping terms.

Knowing why and how to source from China is only half the battle. Your brand's ultimate success depends on finding the right manufacturing partner. Carefully vetting potential suppliers is critical.

Use this checklist to evaluate potential factories. A good partner should meet all these requirements.

Specialization: Does the factory specialize in your product type? A factory excelling at knitwear like T-shirts and hoodies will produce better results than one primarily making woven jackets.

OEM vs. ODM: Understand what you need. OEM (Original Equipment Manufacturer) is when you provide complete tech packs. ODM (Original Design Manufacturer) is when you select and modify existing factory designs. Versatile partners should offer both.

MOQ Flexibility: Can they support your current order size? More importantly, can they scale with your growth? Ask about MOQs for different product types.

Communication: Are they responsive, fluent in English, and proactive in asking clarifying questions? Good communication is the foundation of successful partnerships.

Experience & Portfolio: Have they worked with international brands before? Ask to see work examples or brand lists they've produced for (if not confidential).

Quality & Compliance: Do they have clear quality control processes? Can they provide evidence of social compliance audits or quality management certifications like ISO 9001 or BSCI?

Good partners are transparent about their capabilities. Check their websites for clear service presentations, like the OEM/ODM services detailed on hzaqii.com.

Be wary of suppliers showing these warning signs during initial conversations.

Vague answers on pricing, MOQs, or production timelines.

Unwillingness to create full sets of pre-production samples.

Poor communication, long response times, or language barriers.

No verifiable factory address, photos, or business license.

Pressure to pay 100% of costs upfront.

After understanding criteria for reliable manufacturers, the next step is finding one. Based on proven track records, specialization, and complete service systems, we can confidently point to a premier choice.

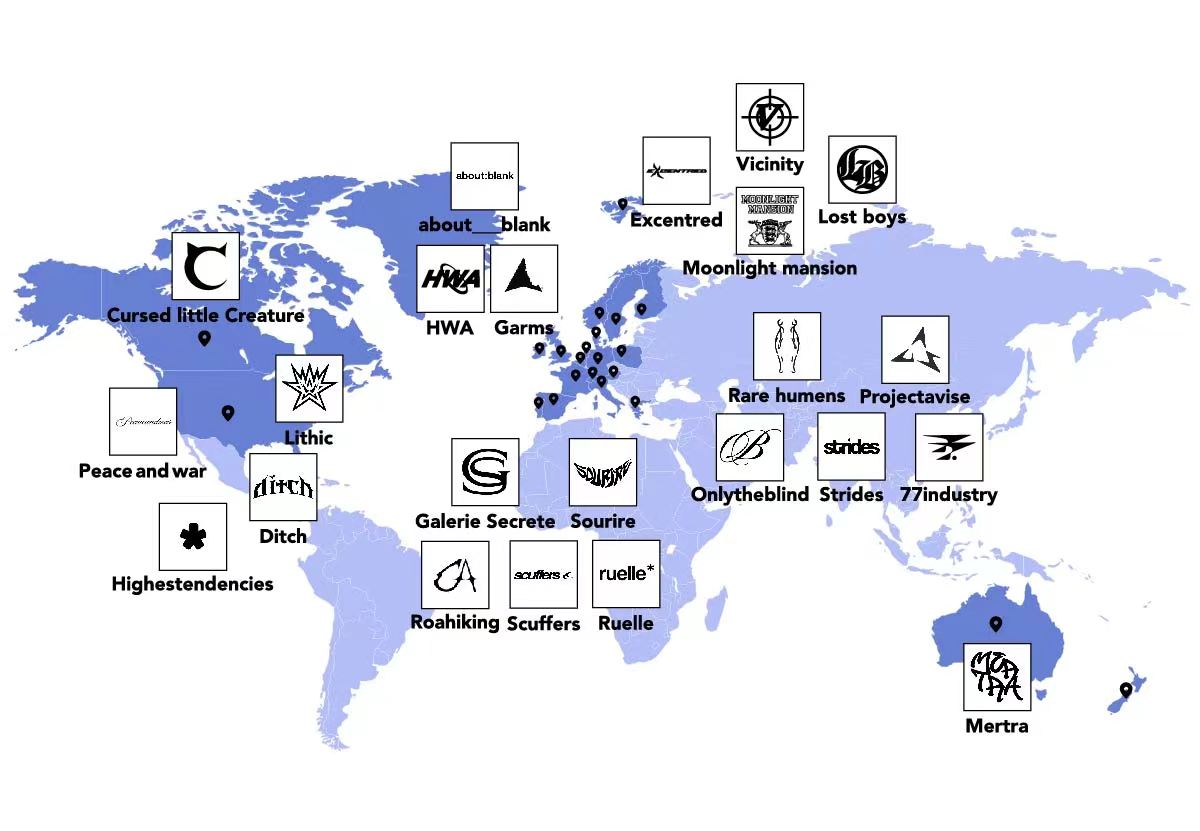

Our factory mainly provides custom clothing services, including customization of fabrics, zippers, labels, packaging, and more. Currently, we collaborate with multiple brands in European and American countries, such as Vicinity, Moonlight Mansion, Lost Boys, 77Industry, Sourire, and others.

Based on criteria for reliable partners, Hangzhou Aiqi Clothing Technology Co., LTD stands out. This is especially true for brands in streetwear, sportswear, and contemporary fashion spaces.

They are specialists. Their expertise focuses on exactly what this guide covers: high-quality T-shirts, hoodies, tracksuits, sportswear, and related knitwear. This focus ensures deep knowledge of right fabrics, fits, and construction techniques.

They offer a full OEM/ODM system. This makes them perfect for any brand. Whether you come with complete tech packs ready for production (OEM) or have ideas needing their design team's help (ODM), they have the infrastructure to support you.

They have proven international experience. Working with brands worldwide has refined their communication systems. They understand global quality standards and market trends.

They are flexible and scalable. Aiqi Clothing serves emerging brands requiring flexible MOQs to start and larger companies needing stable, high-volume production partners for core collections.

Their extensive experience reflects their commitment to quality and client collaboration. Learn more about their company philosophy and history on their About Us page.

Understanding why brands source T-shirts and hoodies from China is the first step. Next is finding the right partner to bring your vision to life. Aiqi Clothing provides complete support systems, from initial design consultation to final delivery.

They act as more than manufacturers. They're strategic partners invested in your brand's growth. Their team guides you through fabric selection, sample development, and the entire production process.

For brands seeking high-quality, efficient, and reliable manufacturing partners for their clothing lines, Aiqi represents a premier choice. They align with all best practices outlined in this guide.

Explore their full range of products and services to see how they meet your brand's specific needs. Visit hzaqii.com to learn more and get in touch with their team.

Sourcing from China isn't just about saving money. It's a powerful strategic advantage when approached with right knowledge and partners. The benefits of integrated supply chains, massive scalability, advanced craftsmanship, and superior cost-effectiveness are achievable for brands of any size.

The key is moving beyond searching for the "cheapest" supplier. Focus on finding the best value. This means partners who communicate clearly, deliver consistent quality, and can grow with your brand long-term.

Follow the playbook outlined in this guide. Create detailed tech packs. Navigate the sampling process carefully. Vet your partners thoroughly. This builds resilient and profitable supply chains.

Great apparel brands start with great products. Partnering with world-class manufacturers in China is one of the most effective ways to ensure you deliver excellent products to customers. Your journey to building a global brand starts with a single, strategic step.